With the competition of intelligent devices becoming more and more fierce. Many manufacturers hope to highlight themselves through the differentiation of hardware and technology. Many times, before we understand the new technology, new technology concepts appear in the market, such as in cell, on cell and OGS Optical Bonding technology, which are hot in the touch market.

Due to the rise of new concepts, many end customers who are new to the industry or making related finished products may not be very familiar with this series of concepts. Therefore, this article is mainly for customers to understand the classification of full lamination technology and the differences between various processes. Let’s learn about it together.

This article is divided into Four parts

- Type of the Touchscreen Bonding methods

- Optical bonding technology(Incell& Oncell&OGS)

- Comparison of full bonding process: Incell Vs Oncell

- Conclusion

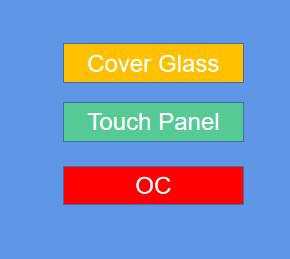

From the structure of the screen, we can roughly divide the screen into three parts, from top to bottom, namely, protective glass, touch screen and LCM. These three parts need to be bonded. Generally speaking, they need to be bonded twice. One bonding is between the protective glass and the touch screen, and the other bonding is between the lcd module and the touch screen.

Bonding Methods

According to the bonding method, it can be divided into full bonding and frame bonding:

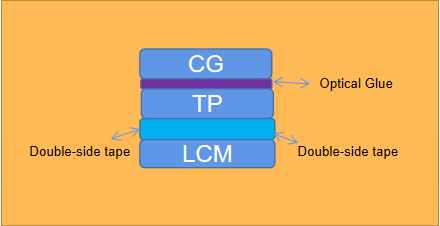

Frame Bonding

The Frame bonding is also called word glue bonding. That is, simply fix the four sides of the touch screen and the display with double-sided adhesive, This is also the fitting method used by most displays in the past. Its advantages are simple process and low cost. However, because there is an air layer between the display screen and the touch screen, the display effect is greatly reduced after light refraction, which is the biggest defect of frame bonding. As shown in the figure below:

Full Bonding/Optical Bonding

Full bonding means that the panel and the touch screen are completely bonded together in a seamless manner with water glue or optical glue. It can provide a better display effect than frame pasting.

As shown in the figure below, there is no air between the screens of full lamination technology, which can greatly reduce light reflection, reduce light loss and thus improve brightness. However, if glue is used for bonding, the input cost is higher and the rework is more difficult.

Advantages of full lamination: the full lamination technology eliminates the air between the screens, which helps to reduce the reflection between the display panel and the glass, makes the screen more transparent and enhances the display effect of the screen.

Another advantage of the full lamination technology is that the screen will no longer be gray. The strength of the touch module is also improved because it is closely combined with the panel. In addition, the full fit can effectively reduce the interference caused by the noise of the display panel on the touch signal.

Although the advantages of full lamination are huge, the yield rate is relatively low. The consumption and scrapping of surface glass and even panels in the lamination process due to poor yield rate will inevitably lead to an increase in cost. Therefore, the control of defoaming and lamination yield rate will become a more important factor than the material cost.

Optical bonding technology(Incell& Oncell&OGS)

At present, the common full screen in the market is mainly the OGS solution led by the original touch screen manufacturers, and the on cell and in cell technology solutions led by the panel manufacturers.

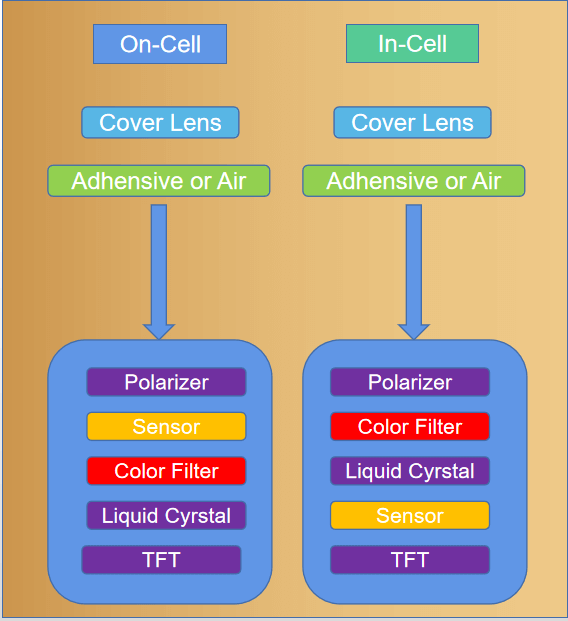

In-cell Technology

In cell refers to the method of embedding the touch panel function into the liquid crystal pixel, that is, embedding the touch sensor function inside the display screen, which can make the screen lighter and thinner. At the same time, the in-cell screen must be embedded with a matching touch IC, otherwise, it is easy to cause wrong touch sensing signals or excessive noise.

As one of the three full bonding technologies introduced today, in cell has the highest process difficulty, mainly because it integrates the touch layer and the display layer. This is to further reduce the overall thickness of the whole screen and make it lighter and thinner. As the air layer is further reduced, OCA only needs to appear once, which is used to paste the two-layer structure of protective glass and “touch display layer”. In short, in cell ensures the normal operation of the touch function by adding a separate touch IC to the display layer.

Therefore, for any display panel manufacturer, the threshold for entering the in cell / on cell touch screen technology is indeed quite high, and it still needs to overcome the difficulty of low yield. Once in cell is damaged, not only the touch screen will be lost, but also the display screen will be scrapped. Therefore, manufacturers have higher requirements for in-cell yield.

On-Cell Technology

On cell refers to the method of embedding the touch screen between the color filter substrate and the polarizer of the display screen. That is, the touch sensor is equipped on a liquid crystal panel, which is much less difficult than in-cell technology. In the past, on-cell was mostly applied to AMOLED panel products, but it has not been able to overcome the problems of thinness and uneven color caused by touch. Now, due to technology upgrading, many TFT products also use on cell technology, and the process yield has been greatly Improved.

OGS /TOL Technology

OGS technology integrates the touch screen with the protective glass, coats the ITO conductive layer on the inner side of the protective glass, and directly conducts coating and photolithography on the protective glass. Since a piece of glass and a bonding are saved, the touch screen can be made thinner and the cost is lower. However, OGS still faces the problems of strength and processing costs.

Since the OGS protective glass and the touch screen are integrated, they usually need to be strengthened first, then coated, etched, and finally cut. It is very troublesome to cut the reinforced glass in this way, with high cost and low yield, and some capillary cracks are formed at the edge of the glass. These cracks reduce the strength of the glass. At present, insufficient strength has become an important factor restricting the development of OGS.

In the internal documents of some touch manufacturers, tol (touch on the lens) is used to describe OGS, which means the same thing. Of course, there are other OGS-like full-screen structures, such as GG, gG2, GF, etc.

In-cell VS on-cell

Currently, on cell and incall technologies are most used in the application of display screens. The structures of in-cell, on cell, and OGS are different, which makes the screen light and thin, display effect, manufacturing cost, and yield different, mainly reflected in the following points:

- Visual effect

Theoretically, in cell makes the screen less than one layer, and the screen is clearer than on cell.

- Thickness

In cell is lighter and thinner than on cell.

- Screen strength

On cell is more resistant to falling than in cell. In cell fuses the touch layer with the liquid crystal layer. If there is a problem with the touch screen, it should be replaced together with the display panel.

- Production difficulty

In the early stage, in cell was more difficult to control production than on cell. With the maturity of in cell manufacturing process, the production control technology of in cell and on cell tended to be stable.

- Touch sensitivity

The in cell screen directly integrates the touch layer and the liquid crystal layer. The sensing noise is large, and a special touch chip is required for filtering and correction.

- Yield

The yield rate of in cell and on cell screens is at the same level, and large-scale shipment is not a problem.

Conclusion

On cell adds a touch layer, and the thickness will be increased to a certain extent, and the display effect is limited. In cell embeds a touch sensor in the pixel, and the area that can be used for display will be reduced, which will lead to image quality degradation to a certain extent. However, this is not a serious problem and can be compensated by using a touch chip. If it goes on like this, either G + G or G + F, or OGS will eventually be replaced by on cell, while on cell is only the transition of in cell, and only in cell will survive in the end.

With the popularization of liquid crystal integration technologies such as on cell mode, there is no need to use external touch panel components. The manufacturers of touch panels are likely to transform from the original external touch panel manufacturers to liquid crystal panel and color filter manufacturers. The original supply chain in which product manufacturers purchase external components from touch panel manufacturers will also be completely changed.

One Response

Merci pour les explications ,elle sont claires et bien précise